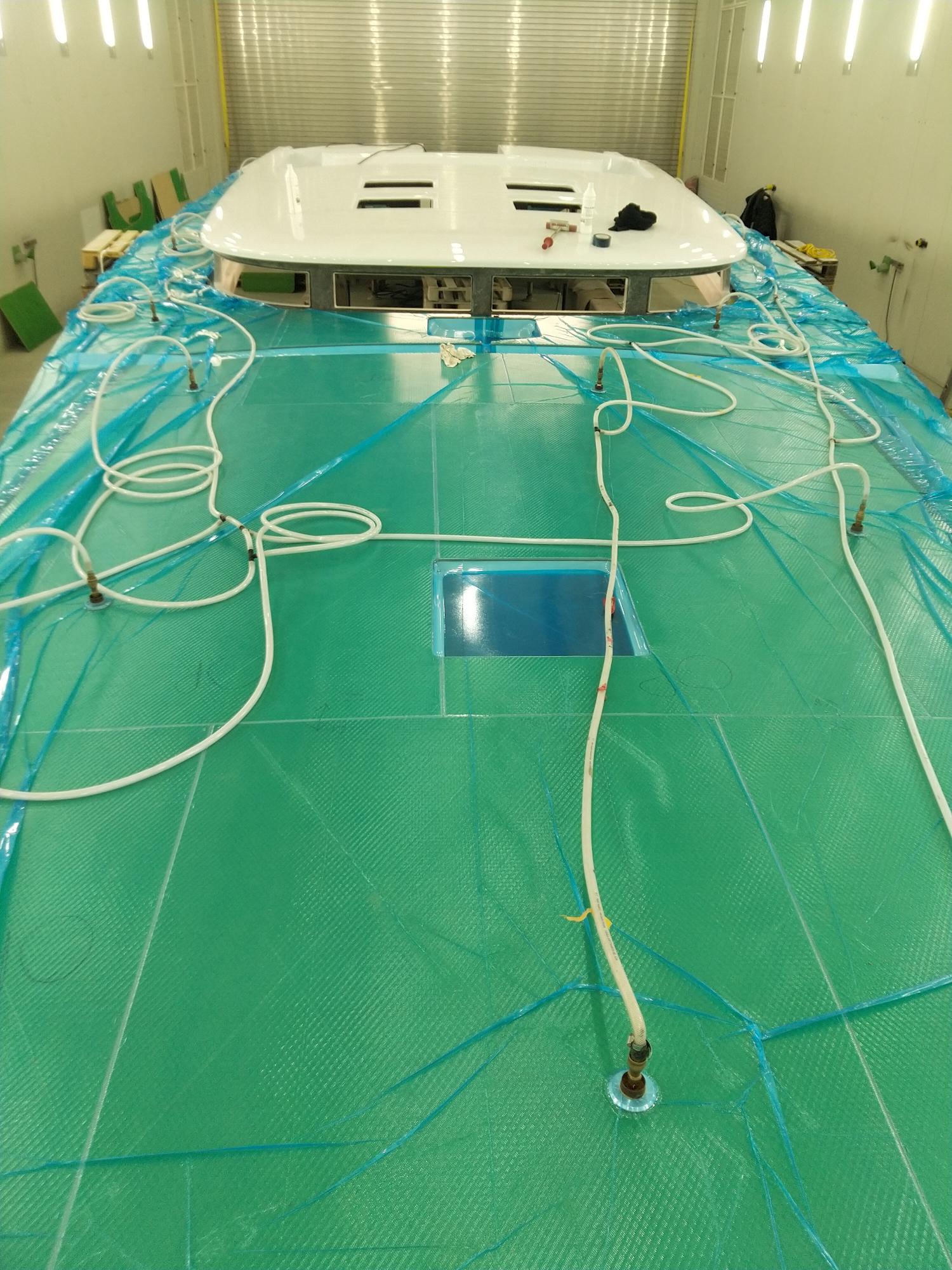

Vacuum bonding is a modern technique which requires knowledge and needs material and therefore an additional cost, but it is the best solution if you want an optimal level of finish and a good gluing hold over time. To perfect our work, we make a peripheral seal using UV protected adhesive sealer, to guarantee the sealing and the final aesthetics. Concerned about the environment, we reuse as much as possible the wooden templates as well as the plastic membranes, otherwise we evacuate them in the sorting circuit.